|

Visiting Cape Cod? Check Out This Hidden Gem: Sydenstricker Glass, Brewster, Massachusetts After a snow-filled winter, I decided to go to Cape Cod for a couple of days. Stopping at the tourist booth along the way, I found a unique place you might like to visit: Sydenstricker Glass (490 Main Street, Brewster, Massachusetts, 508-385-3272). After driving to Brewster along curvaceous Cape Cod roads, I walked down a brick path behind the Sydenstricker Glass gallery to the workshop, which you can visit. Bill Sydenstricker founded the company during the 1960s. Through his research on early Egyptian art while a student at MIT, Mr. Sydenstricker developed the unique glass craft practiced here. Tom has been at Sydenstricker for 39 years and Jenn for 17 years. They work in a glass-enclosed area with filters to prevent them from breathing in powdered glass. Starting with clear glass sheets, each artisan places a manila-folder stencil on top of the glass.  The glass designs require stencils: anywhere from two to seventeen. A new sunflower pattern, for example, requires six stencils. The first three stencils require mostly yellow, orange, and red glass powder forming the flower petals. The top three layers of stencils form the green leaves. Through a small sieve, each color of powdered glass is tapped with a well-worn spoon onto its designated stencil. Each stencil layer must be removed carefully to not ruin the pattern. Once the pattern is complete, excess powdered glass is removed with a flat razorblade. Another clear glass square is placed on top to start a new glass plate design. Pairs of glass sheets fuse in the kiln, where they are fired for five hours at 1,500 degrees Fahrenheit. They conform to the shapes of the molds. The glass then cools in the kiln for 40 hours. The cost of each plate depends on the amount of kiln space it requires. The result is unique and highly sought-after. United States presidents, Queen Elizabeth II, and the Pope own Sydenstricker glass! Popular Sydenstricker patterns include hydrangeas (four stencils) and blueberries (seven stencils). The company's first paper pattern is The White Daisy. The Embassy, the company's first geometric pattern, is thus named because the patterned plates grace many embassies around the United States. Posted By Karen Axelrod on May 23, 2019

Second Wind Brewing Company On my drive back to Boston from Cape Cod on a sunny, chilly, windy December Saturday (aren’t they all chilly in December in Massachusetts?), I stopped in Plymouth for a fried scallop plate at Woods Seafood and then went to Second Wind Brewing Company.  The brewery's unassuming premises are in a garage behind an apartment complex.  So it has no parking. However, you can park down the street, and it's worth the water view!  As I walked up the street to the brewery, seagulls cawed overhead. On this chilly Saturday the brewery's tap room, which opened in May, was quite crowded. Upon entering the front door, I had to jostle my way gently to the bar in a bit of friendly human Tetris. With only six seats at the bar, most people stand. Once you get through, choose between the eight different beers on tap (these change weekly or every other week). Enjoy a pint or choose any four 5 oz. pours.  Scottie will mark your four choices with a marker on a metal muffin tin and ask whether you want pretzels. When he delivers your four pours in the muffin tin, he will recommend the best order in which to drink them.  The beer is brewed right on the premises.  In the summer, the brewery's space expands to include an outdoor beer garden under a red tent. I hope to return then, on a much less chilly Saturday! Posted By Karen Axelrod on Jan 10, 2019

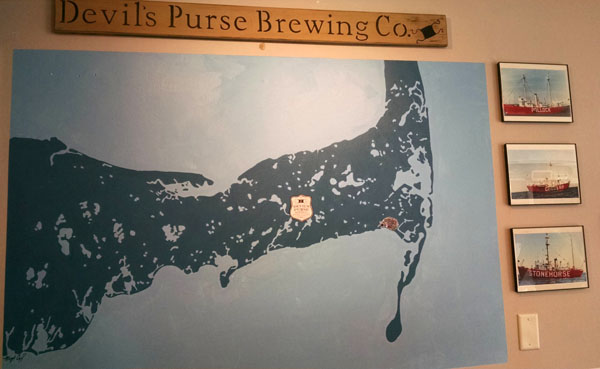

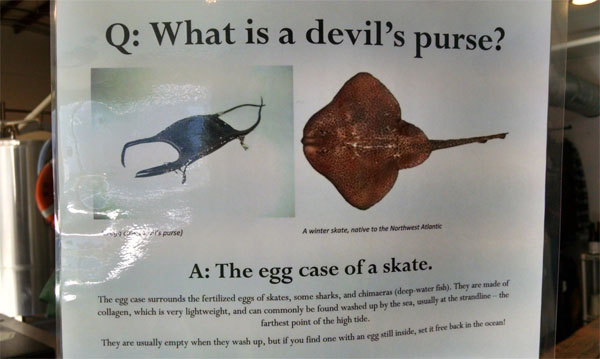

I recently had a chance to tour Devil's Purse Brewing Company, located in South Dennis, in the middle of Massachusetts summer haven Cape Cod.  Devil's Purse was founded in 2013. Previously in the wine business, the owner decided to try his hand at home beer-brewing. When it came time to name his new company, he wanted a Cape Cod connection without being too obvious. The inspiration came from the skate egg cases, traditionally called devil's purses, that wash ashore on New England beaches and which he used to collect while growing up on the Cape.  If you're on Cape Cod, the company is worth a visit! You can hang out in the tasting room at Devil's Purse...  ...and visit the shop.  Posted By Karen Axelrod on Jul 31, 2018

As explained in our previous blog piece, during a three-week trip to China we had the opportunity to see how tofu is made in that country, where it originated. After our visit to a tofu-making site in the Guangxi region, we visited another in the province of Anhui. A five-hour ride on a high-speed bullet train took us from Shanghai to the Yellow Mountains, where we drove 30 minutes to Xuan Yuan farm. There we witnessed a slightly different way of making tofu (doùfu in Mandarin) from the way we had seen in Guangxi. The tofu-maker, Mr. Hu, showed us soybeans that he had been soaking for 8 hours (the process takes 12 hours in the winter). With a metal strainer, he scooped the beans out of a deep white bucket into a deep white plastic strainer.  Using half a dried gourd, he scooped the soybeans into the top funnel of a grinding machine.  When he turned the grinder on, white liquid streamed out both sides. Next, Mr. Hu poured the white liquid into a cauldron, which he covered with two semicircular wooden lids.   He added wood to the fire at the back of the stove and boiled the soybean milk for 40 minutes at 108 degrees Celsius. As the mixture boiled, we walked around the farm and enjoyed the sweet fragrance of the wisteria. We passed the farm’s chicken coop and were offered fresh eggs to purchase. We then walked into some of the hoop houses for growing vegetables.  At the far end of the property, we walked along rows of peach trees and watched the farm’s 300 ducks waddle back and forth.  After we returned, Mr. Hu ladled the steaming hot tofu mixture into square wooden frames lined with cotton cheesecloth-like fabric.  He poured some into paper cups for us to sample with spoonfuls of white sugar.  Mr. Hu gently folded the fabric over each wooden frame filled with the mixture, which looked like curds of cottage cheese. Once he had covered the frames, he removed the outside edge of each and stacked all three on top of each other. He lowered the overhead wooden beam to add weight and quicken the water drainage. Lastly, he cut up squares from the tofu he had made that morning and put four pieces in a small, clear plastic bag. We also sampled soy-sauce-marinated tofu that had been pressed by hand in cotton cloth into wafer-thin squares. The next evening, we enjoyed the fresh tofu in the spicy Szechuan style. We learned with delight that Mr. Hu wants to bring this way of making tofu to America. Posted By Karen Axelrod on Sep 14, 2017

|

Archives2019 2018 2017 2016 2015 2014 2013 2012 2011 2010 2009 2008 2007 |